Phenomenon 1: The mouth of the bottle expands, and the bottle runs out of gas

Reason: As the temperature of the surrounding space gradually increases, the cooling effect of the airflow passing through the oven is reduced, and as a result, the temperature of the mandrel rises, which is transmitted to the thread area.

Solution: External cooling can be used to control the temperature of the thread area and the mandrel when the preform passes through the oven; adjust the position of the cooling plate so that the thread area of the preform can be more protected. In addition, a well-designed cooling plate may be a better countermeasure.

Phenomenon 2: The bottom is damaged

Reason: The temperature at the bottom of the preform is too low, and when the stretch rod moves towards the bottom of the mold, micro-cracks are formed.

Solution: The best solution is to keep the end of the preform neither too cold nor too hot between stretching and breaking. In addition, the clearance from the stretch rod to the bottom of the mold is also critical, and only the maximum necessary clearance can be used to ensure the positioning of the door.

Phenomenon 3: Transition

Cause: Problematic cavities may be caused by insufficient air blowing. If the temperature of the preform during blowing is lower, the bubble blows more slowly, and the problem is more obvious. The light bottom also means that the material has reached its natural stretch limit before the entire container can be formed.

Solution: Make sure that all the ventilation holes on the mold are not blocked; make sure that the blowing can be completed in the shortest time, otherwise, it will bring additional cooling to the PET material when blowing the bottle; check the working condition of the road valve to ensure the blowing accurate positioning.

Phenomenon 4: The neck is bent

Reason: This problem is generally caused by mechanical operation, and the neck is too thick to cause deformation after clamping.

Solution: The bottle neck is too thick, and the bottle neck will become crooked when it is touched by the mold; in addition, the alignment of the conveying arm and the blowing center is also a cause of this problem.

Phenomenon 5: The screw part of the bottle mouth is damaged

Reason: The preform is fed into the mold cavity by the conveying arm. When clamping, the thread side must be stressed. When the conveying arm is in an inaccurate position, when it lifts the preform ring from the top of the mold, if the weather is cold, the blowing core will press When it reaches the closed surface of the preform, it will play a pressing role, and it will not cause damage. Unfortunately, in hot weather, the venting of the threads is subject to tensile forces, as the preform is forced into alignment by the blow core that has been washed down.

Solution: Make sure that the adjustment of the conveying arm is accurate; also, the alignment of the mold at the blowing core site is also related.

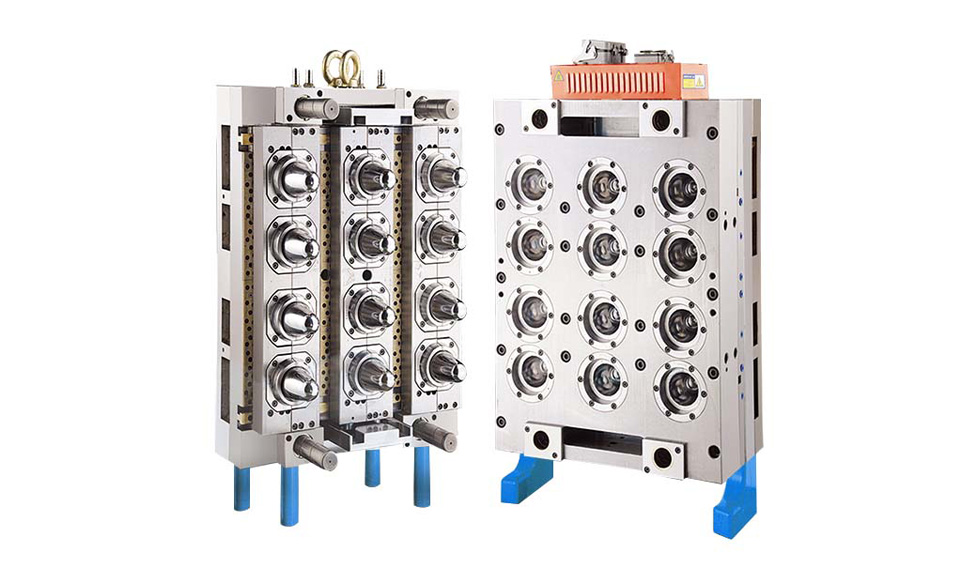

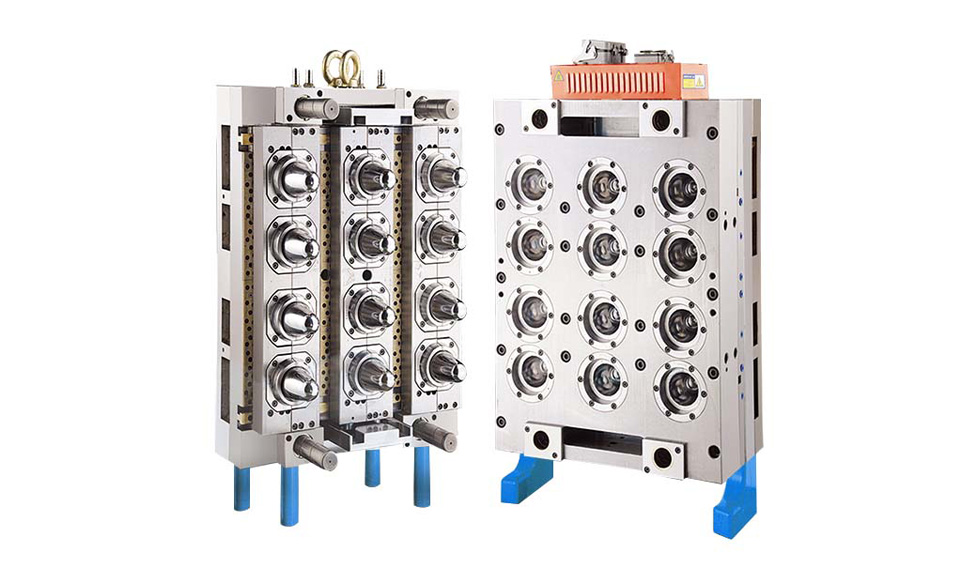

Master Packing Co.,Ltd was founded in 1997, is a professional China PET preform molds manufacturers and PET preform moulds factory. Because of Advanced CNC machinery, 5 axis drilling machine, Lathe, a group of more than 15 years experienced engineers, Master brand Packing machine now exported more than 87 countries and district.Master Packing focus on Injection mold machine, PET/PP bottle blowing machine, PET/Glass/Can filling line and custom PET Preform Molds for sale, Also Master Packing supply the labeling machine and molds. Master packing design and manufacturing the simplest machine, let customer has ability to run and operate the machine in short time, Meanwhile, Master packing is strict with the quality control, Supply customer with stable and long life machine.

Master Packing Co.,Ltd was founded in 1997, is a professional China PET preform molds manufacturers and PET preform moulds factory. Because of Advanced CNC machinery, 5 axis drilling machine, Lathe, a group of more than 15 years experienced engineers, Master brand Packing machine now exported more than 87 countries and district.Master Packing focus on Injection mold machine, PET/PP bottle blowing machine, PET/Glass/Can filling line and custom PET Preform Molds for sale, Also Master Packing supply the labeling machine and molds. Master packing design and manufacturing the simplest machine, let customer has ability to run and operate the machine in short time, Meanwhile, Master packing is strict with the quality control, Supply customer with stable and long life machine.

English

English España

España