Problem 1: Plastic is wavy

reason:

Due to the narrow gate or other parts, when the molten plastic pushes the solidified plastic part forward, the surface is corrugated, which is how it comes.

Solution:

①Increase the

injection diameter; ②Increase the temperature of the injection nozzle and mold; ③Increase the height of the barrel; ④Increase the injection speed;

Problem 2: The plastic parts are in the shape of silver streaks

reason:

Due to the water content of the plastic, the mixing is uneven, the air is included during injection molding, and there are too many additives or mold release agents.

Solution:

① Strengthen the back pressure; ② Slow down the injection speed; ③ Clean the barrel; ④ Increase the mold temperature; ⑤ Change the gate position; ⑥ Expand the runner and gate;

Problem 3: Poor plastic interface

reason:

Hair-like thin lines or bubbles are generated because the plastic temperature is too low to melt, or due to insufficient gas excretion resulting in the mixing of more than two shunts.

Solution:

①Increase the material temperature; ②Increase the injection temperature; ③Increase the injection speed; ④Set up a cold material pool outside the seam line; Flowing low viscosity of raw material.

Problem 4: Plastic parts show voids

reason:

Because the surface of the plastic contacts the low-temperature mold wall during the solidification of the melt, the shrinkage is concentrated in the thick-walled section, resulting in voids, or voids due to air inclusions.

Solution:

①Increase the injection pressure (and secondary pressure); ②Extend the injection time; ③Reduce the curing temperature of the barrel; Mouth; ⑥ Shorten the runner; ⑦ Mix the mold temperature thoroughly; ⑧ Change the gate position to eliminate air inclusions.

Problem 5: Underfill or lack of material for plastic parts

reason:

Due to insufficient mechanical injection and plasticizing performance, poor material flow, too thin gate section, too thin mold wall or poor deflation.

Solution:

①Increase the injection rate, if it is still insufficient, you need to replace the heavy machinery; ②Install the leak-proof injection valve screw; ③Increase the injection pressure; ④Increase the temperature of the barrel, the injection nozzle and the mold; ⑥Check whether the nozzle is blocked and increase the circulation speed; ⑦Increase the mold deflation capacity; ⑧Increase the gate section; ⑨Increase the wall thickness of the product; agent.

Problem 6: Extrusion of plastic while clamping

reason:

Due to high material temperature and injection pressure, or insufficient clamping force.

Solution:

①Reduce injection pressure and barrel curing temperature; ②Short injection time; ③Reduce injection speed; ④Use high clamping force machine;

Problem 7: The surface of the plastic part is dented

reason:

Due to the delayed cooling of the surface of the plastic part, its surface is dented.

Solution:

①Increase the injection rate; ②Increase the inner pressure of the mold cavity (secondary pressure); ③Reduce the curing temperature of the barrel; ④Increase the injection flow rate; ⑤Increase the injection rate; ⑥Extend the injection time; position; ⑨ expand the gate; ⑩ shorten the mold runner.

Problem 8: Plastic parts are twisted and deformed

reason:

Plastic parts are deformed and distorted due to the relaxation of residual stress in injection molding.

Solution:

①Reduce the injection pressure; ②Reduce the solidification temperature of the barrel material; ③Extend the cooling time;

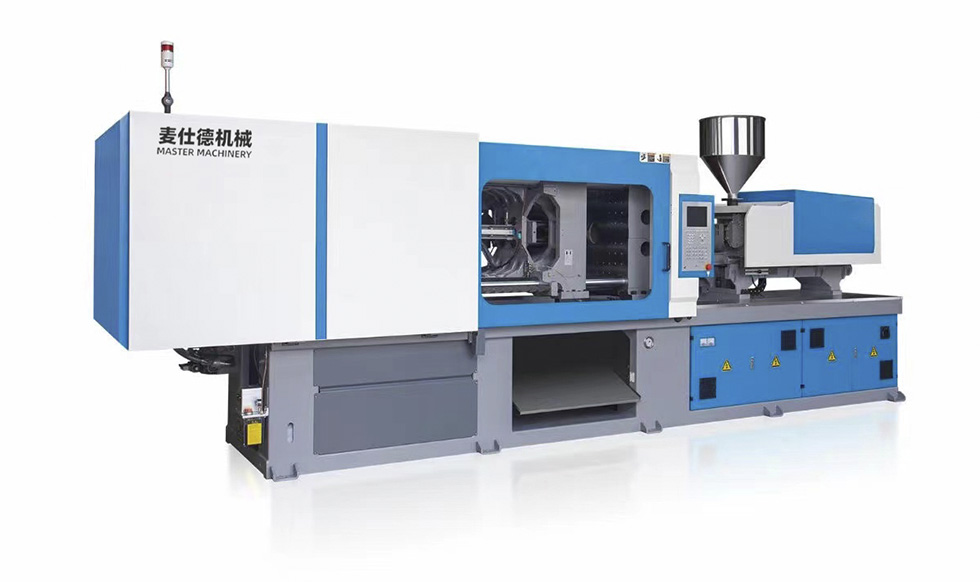

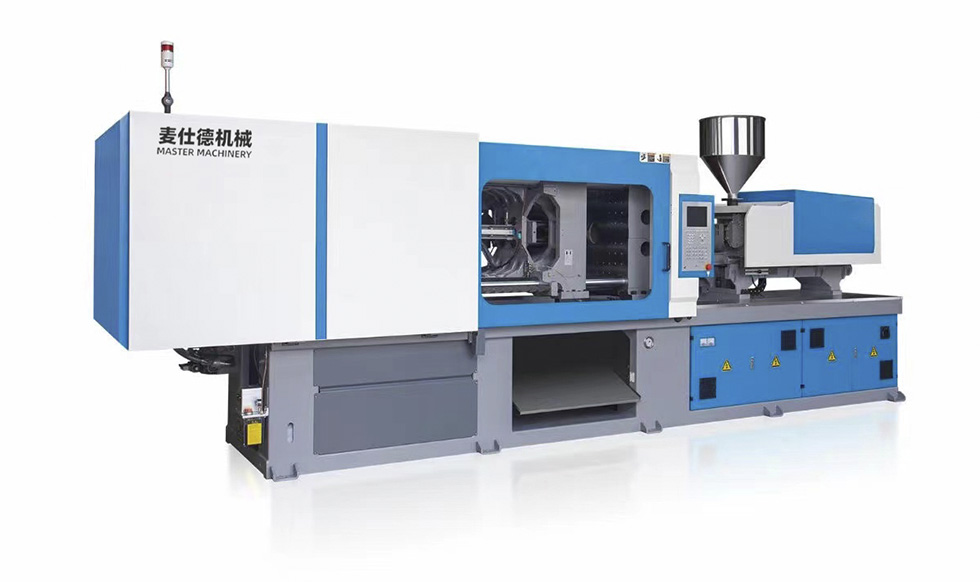

Thermoplastic Injection Molding

Master Packing joint with Ningbo injection company to supply customers with 10T-4,000T, injection weight 45g---40,000g, more than 30 kinds of specification injection mold machine. Master injection machine has energy-saving, environment-friendly, low noise, high rigidity, excellent performance, fast response, and high efficiency. With advanced servo motor and famous brand parts, Master injection machine becomes many customers' optimal choice for Injection needs.

English

English España

España