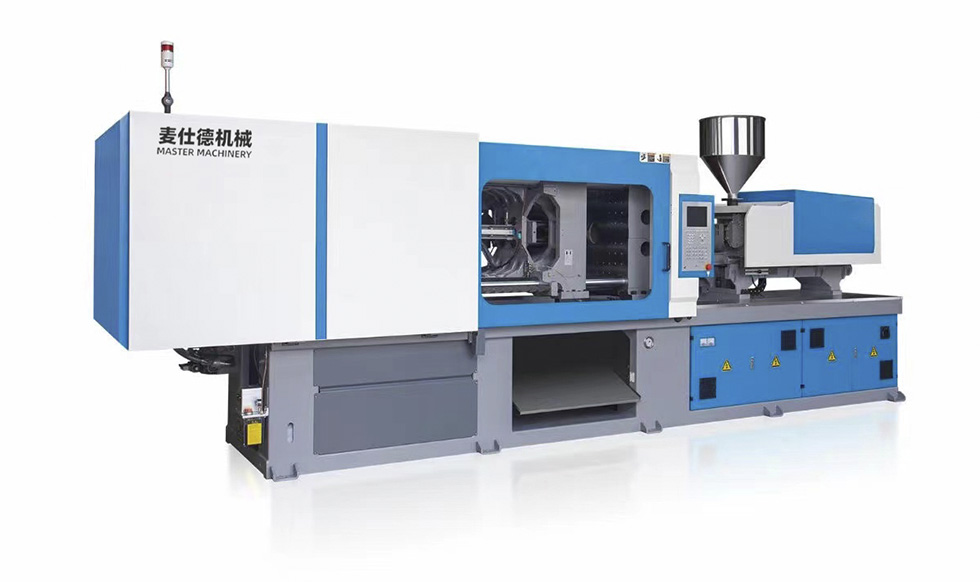

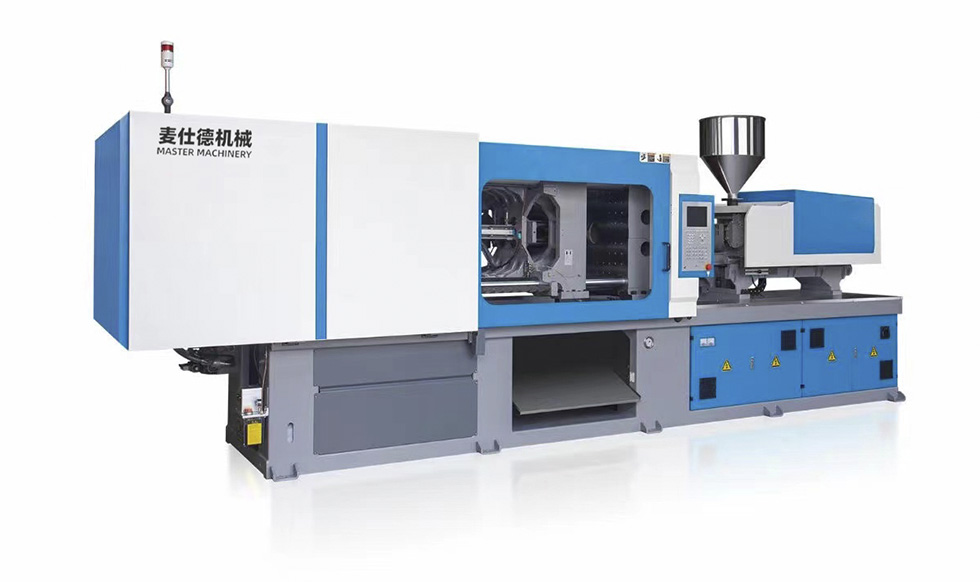

Injection workshop working steps and precautions

1. Preparations before starting

1. Purpose:

To ensure the normal operation of the machine after it is turned on, to avoid accidents.

2. steps, methods

1> The operator first checks the machine to ensure that the surrounding area of the machine is clean and that no foreign objects block the machine and workstation.

2> Check whether the electrical equipment is clean and whether the insulation facilities have leakage. If there is any problem, it must be solved first.

3> Check whether the lubrication system and cooling system are smooth and whether there is leakage.

4> Check whether the mechanical safety device is out of order, check whether the fastening screws of the safety device are loose, whether the mold tightening nut is loose, whether the parameter setting of the mold opening and locking on the display screen is abnormal, and whether the selected automatic and semi-automatic modes are normal.

5> If the above is normal, start the motor, open the front and rear safety doors respectively, and manually operate the machine to check whether there is a mold-locking action.

2. Start-up trial operation

1. Purpose:

Check whether the machine can work normally.

2. steps, methods

1> Turn on the power and start the motor.

2> During the formal operation, the operator should also pay attention to listen to whether the sound of the oil pump motor is normal, whether there is noise, whether there are other abnormalities in the moving parts of the machine (such as machine twister, curved hand, cross head, etc.) and mold opening and mold clamping. sound.

3> If the machine and the mold are in normal operation, the machine can be officially turned on.

3. Precautions

1) Once the operator finds a machine failure or electrical failure, he should immediately stop the oil pump motor, cut off the power supply, and report to the workshop manager immediately.

3. Start production

1. Purpose:

Guarantee the manufacture of qualified products that meet the requirements.

2. steps, methods

1> Preparations before official production

○1 Before production, the operator must first prepare packaging materials (such as cartons, pearl cotton, blister trays, etc.); processing tools (such as nozzle pliers, blades, etc.) according to the products to be produced.

○2 Prepare the workbench and processing position.

2> start

○1 After the operator gets the power-on command, he should be in position immediately. The operator should hold the safety door with his left hand. When the mold is opened, the operator should open the safety door with his left hand and prepare to take the product with his right hand. ) When the product is pushed out, use the right hand to remove the product. Some products need to be taken in the opposite direction. The operator should take it correctly under the guidance of the technician to avoid pulling the product (when taking the product, the hand should not touch the mold.) , to avoid bumps or burns).

○2 After taking out the product, immediately close the front safety door with the left hand, and the machine will proceed to the next cycle.

3> Check the product

○1 After closing the safety door, the operator should self-check the product and compare it with the sample provided by the customer or the quality inspection department. (1) Whether there is any obvious difference in color;

(2) Whether there is a lack of glue (unsaturated), shrinkage, and there is an obvious bonding line;

(3) Whether there are cracks, top height, top white, broken columns, blind holes;

(4) Whether there is obvious drape, drag, splash, or air pattern;

(5) Whether there are obvious color patterns and color spots.

(6) If there is no abnormality, the product can be submitted to QC for confirmation. If it is confirmed to be qualified, the packaging process can be carried out.

(7) If the operator finds that the product does not conform to the model, he must immediately report it to the technical personnel or management personnel for processing until the product is qualified.

English

English España

España