3> Precautions

○1 At present, the front and rear molds of the company's molds must be heated by a 70℃-180℃ mold temperature machine.

○2 When disassembling and assembling the water pipe of the mold temperature machine, be careful to avoid burns.

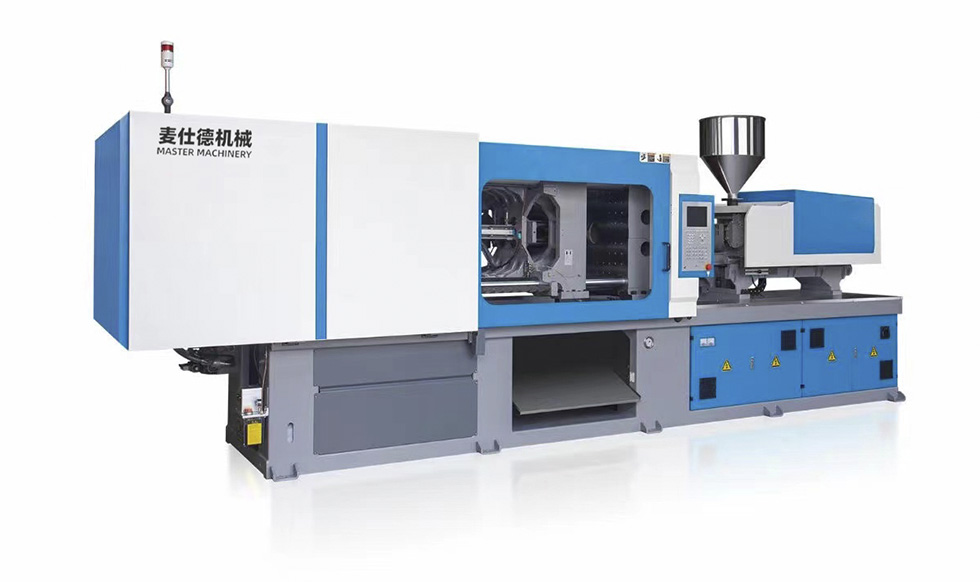

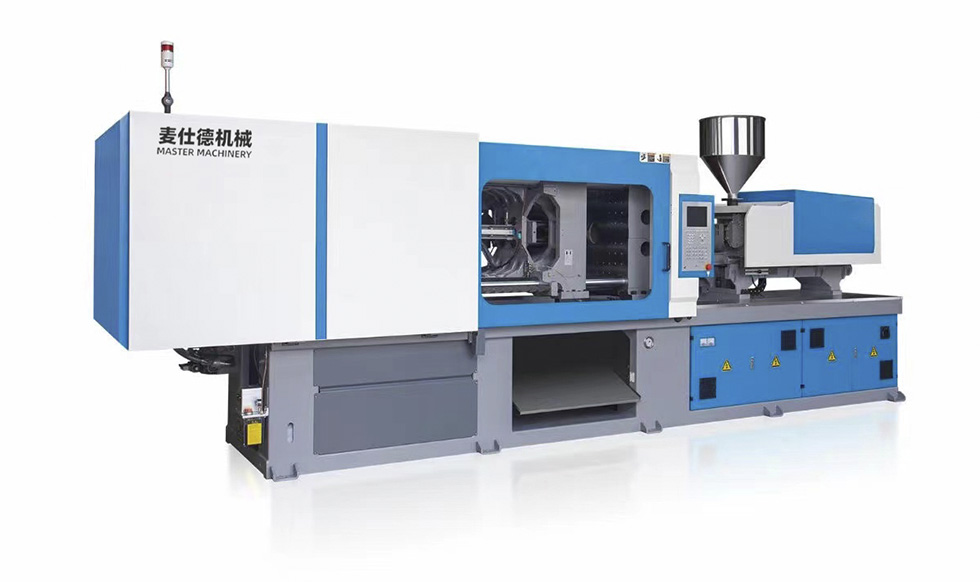

Injection molding machine operation method and precautions

1. Select the semi-automatic or fully automatic function according to the work needs (first familiarize yourself with the function symbols of the injection molding machine).

2. When the semi-automatic function is selected, the operator is responsible for taking the product, and conducting self-inspection on the product, focusing on inspection.

1> Whether the color has an obvious color difference.

2> Whether there is a lack of glue, shrinkage, welding line.

3> Whether there are cracks, top height, top white, broken columns, or holes.

4> Whether there is a front cover, a scratch, or a gas pattern.

5> Whether there is an obvious color pattern, a color mixing point.

3. Pay special attention to the following points during the production process:

1> Take the nozzle first, put it in the carton before taking out the nozzle, do not take the product.

2> Take the product again, pay attention to the tightness of the product in the mold when taking the product.

3> Close the safety door. After the safety door is closed, pay special attention to whether the thimble is retracted to its original position. If the thimble is not retracted in its original position, immediately open the safety door and report to the foreman assistants or workshop managers.

4> The speed of taking the nozzle, taking the product, and closing the safety door seriously affects the output of the day, so the action must be consistent.

5> There are too many scraps in the mold, press nozzle, and production waste, which affect the interests of the self and the company. The reason is that the nozzle has not fallen, the product has not been taken out, and the thimble has not been returned to its original position. Do not close the safety door, and the product must be carried out every 10 minutes. A self-test.

English

English España

España