Blow-molded pallets have always been unique in the plastic pallet industry, and blow-molded pallets have their own unique advantages. The blow-molded pallet can not only meet the use of mechanical forklifts, but also can be used with manual forklifts. The surface of the blow-molded pallet is designed with grooves, and the anti-skid performance is outstanding. At the same time, the use of blow-molded pallets can reduce costs. Next, I will take you to learn more about the knowledge of blow molding trays.

How much do you know about blow molding trays?

1. Manufacturing process and process

The molding process of blow molding tray is the same as the basic method of ordinary plastic blow molding. High polymer high density polyethylene (HMWHDPE) is used for the production of blow molding tray, and the plastic is extruded for one blow molding. The plastic mold is placed in the split mold while it is still hot, and compressed air is introduced into the plastic parison immediately after the mold is closed, so that the plastic parison is inflated and adhered to the inner wall of the mold. Various sizes of blow molding trays.

The production of blow molding trays generally uses HMWHDPE as raw materials. Therefore, its impact resistance and low temperature resistance are the best. The specific process flow of the blow molding tray is as follows: mixing of plastic raw materials → automatic feeding → extruder plasticizing and extruding a stocker head storage → parison injection pre-blowing compressed air → mold clamping machine clamping → compressed air blowing Molding → cooling and forming → product removal → flash removal → weighing → shaping (storage for 24 hours) → fork hole cutting → packing and storage.

2. Molding equipment and molds for blow molding trays

(1) Molding equipment for blow molding trays

The molding equipment for blow molding trays generally adopts large and super large automatic hollow blow molding machine production lines. At present, domestic large and super large hollow equipment manufacturers include Suzhou Jwell Machinery Co., Ltd., Qinchuan Development Plastic Machinery Factory, etc.

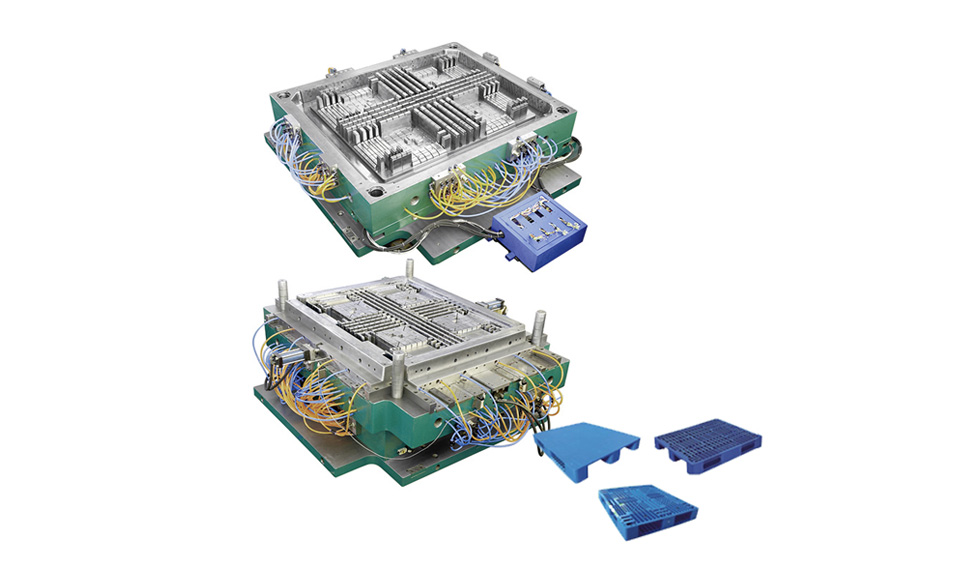

(2) Blow tray forming mold

The molds for double-sided blow molding trays are relatively simple, and the molds for single-sided blow molding trays, shelves, and cold storage blow molding trays are relatively complex. The blow molding tray mold is generally quenched and tempered with 45 steel, and processed by a CNC machining center with a long service life. There are also made of steel molds and aluminum alloys.

Different types of plastic pallets have their own use environments. Before purchasing plastic pallets, you need to understand the size, weight, usage and environment of your own products, and choose the most suitable plastic pallets for your goods according to your needs.

Hign Precision PP Plastic Pallet Mold

Master Packing Co.,Ltd. established in 1997, is one of the leading Bottle Blowing Machine brands in China.

English

English España

España