A China

Injection Machine Factory can meet your need for a high-quality machine. Its machines range in clamping force from 32 tons to 270 tons. In addition, they are available in different specifications and models to meet your specific needs. These companies have a wide range of products and have an impressive growth rate in China.

Injection molding is a highly efficient method of manufacturing plastic products. It minimizes residual scrap and saves money. It produces large numbers of plastic products in a relatively short period of time, and the labor costs are low. Moreover, it features sophisticated technology that ensures a higher level of precision in the finished products. It also allows repeatability of production.

Xinhai Machinery Company is located in Guangdong, China. It provides a one-stop solution for design, manufacturing and research. It has a total production capacity of 10,000 units per day and an 83% CNC utilization rate. The company also has 40 overseas authorized agents. Xinhai has 600,000 square meters of land area.

While looking for a China Injection Machine Factory, you should look at their credentials. You must check out whether the factory has all the certifications necessary for manufacturing plastic parts. You should also ask about the quality standards of the machines. Make sure you visit the factory and meet the senior personnel. At this stage, you can discuss the specifications of your order and negotiate the terms with the manufacturer.

China Injection Machine Factory is an excellent choice if you are looking for an electric or hydraulic injection molding machine. Injection molding machines from China have many advantages over those produced in other countries. They are cheaper, offer better quality, and are delivered faster. And they have many excellent brands to choose from. And they are also equipped with a large labor force, which promotes competition and lower production costs.

Moreover, the China Injection Machine Factory can offer a wide variety of services. You can consult with them on the specifications of plastic molds and injection molds. A quotation sheet will include details like the number of cavities, mold life, gate, surface finish, and price. It will also include the lead time for T1 (the first injection).

Plastic injection molding is a process where raw plastic material is heated and injected into a mold. After cooling, the plastic is shaped into your desired product. The manufacturing process requires technical expertise and attention to detail. Any minor mistakes can prolong the production process and increase the cost of production. So, a China Injection Machine Factory will be your best bet.

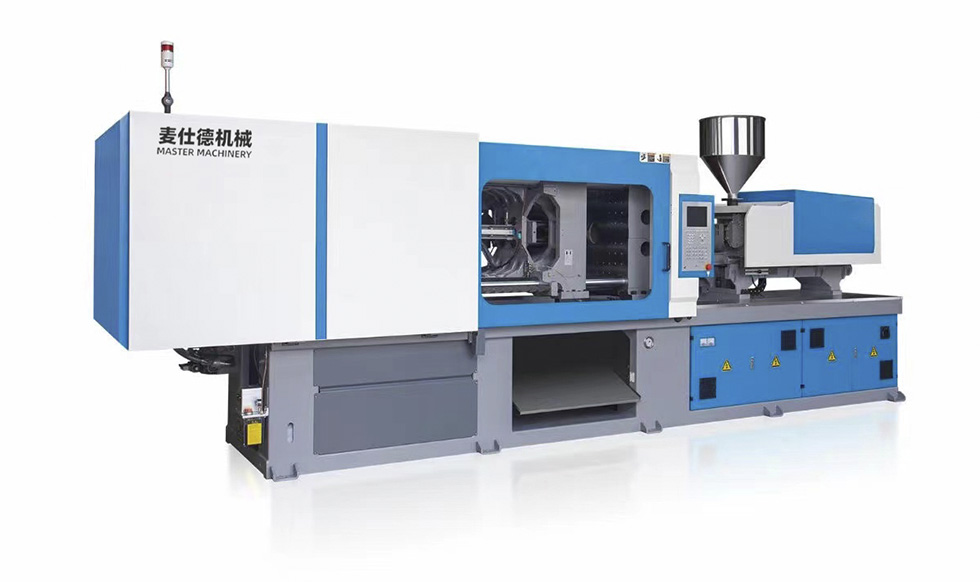

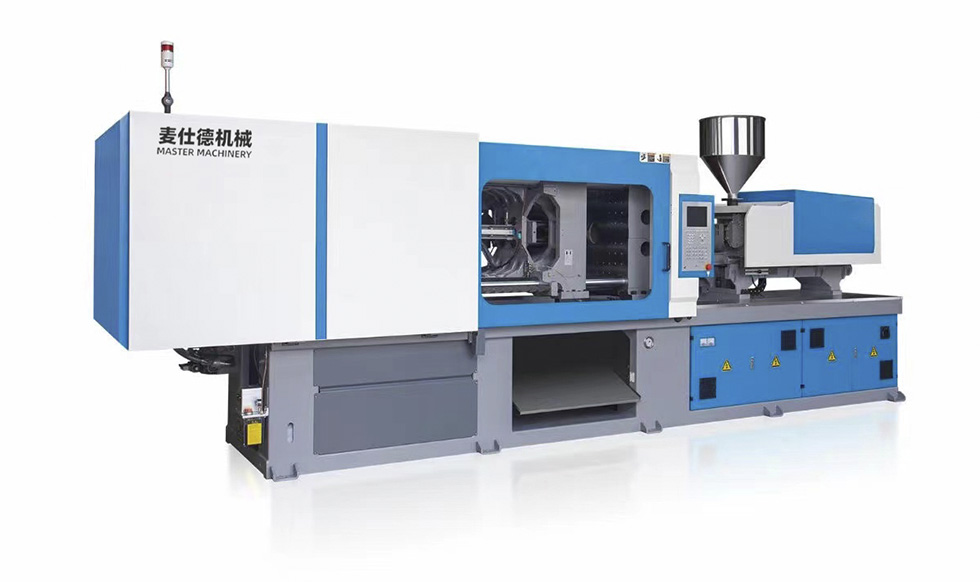

Horizontal Injection Molding Machine

Master Packing joint with Ningbo injection company to supply customers with 10T-4,000T, injection weight 45g---40,000g, and more than 30 kinds of specification injection mold machine. Master injection machine has energy-saving, environment-friendly, low noise, high rigidity, excellent performance, fast response, and high efficiency. With advanced servo motor and famous brand parts, the Master injection machine becomes many customers' optimal choice for Injection needs.

English

English España

España