Beverage

plastic bottle caps are different from others. This directly affects our health and is what we are more concerned about. Generally, we use sterilizing water to sterilize. Unstable elements are present in sterilizing water, and they decompose on their own. Sterilizing water sterilization is to use this decomposition process (oxidation process) to oxidize the microorganisms on the surface of the object, so as to achieve the purpose of sterilization. Common substances with strong oxidizing properties are peracetic acid, ozone water, and chlorine water. The instantaneous sterilization properties of ozone are better than chlorine. At present, peracetic acid and ozone water are basically used for sterilizing water for plastic bottle cap sterilization, most of which are peracetic acid. The higher the concentration of sterilizing water, the shorter the sterilization time required. For peracetic acid at 65°C and 2000PPM, sterilization for 30 seconds to 60 seconds can make the caps meet the requirements of commercial sterility. Due to the short sterilization time and good sterilization effect of sterilization water, it is widely used in the sterilization of bottles and caps of fruit and vegetable juice beverages. The main methods of using sterilizing water to sterilize plastic bottle caps are spray type and immersion type.

The spray type uses multiple sets of nozzles to spray sterilizing water in multiple directions of the bottle cap to sterilize the surface of the bottle cap. The time for the bottle cap to receive the spray should ensure that the microorganisms can be completely killed. The specific method is: the bottle caps after the capping enter the bottle cap track in the same direction, and there are multiple groups of nozzles above and below the track. Each group of nozzles can spray sterilizing water on the bottle caps from different angles. The sterilization of the cap also pushes the cap along the track. When using peracetic acid as sterilizing water, the bottle cap after sterilizing water spraying needs to be rinsed with sterile water to remove the residual peracetic acid on the bottle cap, so that the residual amount is lower than the relevant standard; after rinsing with sterile water Then dry the cap with sterile air. When using ozonated water as sterilizing water, since the decomposed products of ozonated water are water and oxygen, there are no harmful residual substances. In theory, there is no need to reprocess the bottle cap. The distance from the capping machine is very close, and the residual ozone cannot be completely decomposed. Therefore, after the bottle cap is sterilized by ozone water, it needs to be rinsed with sterile water and dried with sterile air. Due to the linearity of the jet water, aseptic water jet sterilization can be used for sterilization of mineral water bottle caps, as well as for bottle cap sterilization during hot filling of tea beverages and fruit juice beverages. Hot filling adopts full bottle filling. After filling and capping, the bottle is inverted to heat the bottle cap for internal sterilization.

The immersion type is to completely immerse the plastic bottle cap in the sterilizing water so that all the inner and outer surfaces of the bottle cap are sterilized by the sterilizing water, and the soaking time should meet the time required for the complete sterilization of the bottle cap. One method is: the bottle caps with the same direction are fixed on the bottle cap frame, the bottle cap frame is connected to the chain, and the movement of the chain drives the bottle cap frame to enter the sterilization tank with sterilizing water and completely soak the bottle caps in the sterilizing water. The soaking time should meet the time required for complete sterilization. Like the spray sterilization method, the caps soaked in the sterilizing water also need to be sprayed with sterile water and sprayed with sterile air to make the caps dry and sterile. When the sterile water sterilization method is adopted, the sterilized water, sterile water, and sterile air that are matched with it need to be produced and processed. There are much peripheral supporting equipment, high supporting cost, high consumption cost, and high management requirements. Therefore, this kind of sterilization process is generally applied to aseptic cold filling of fruit juice beverages.

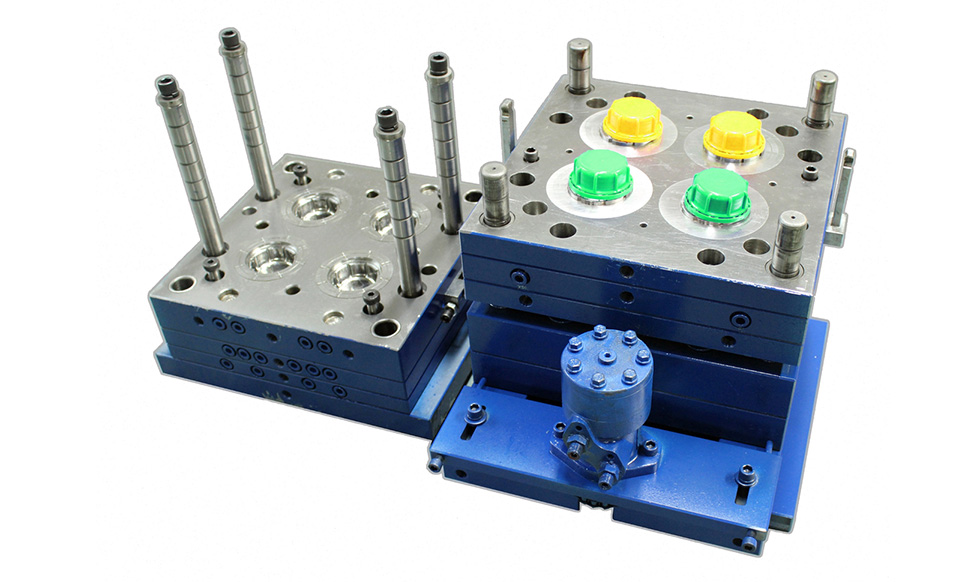

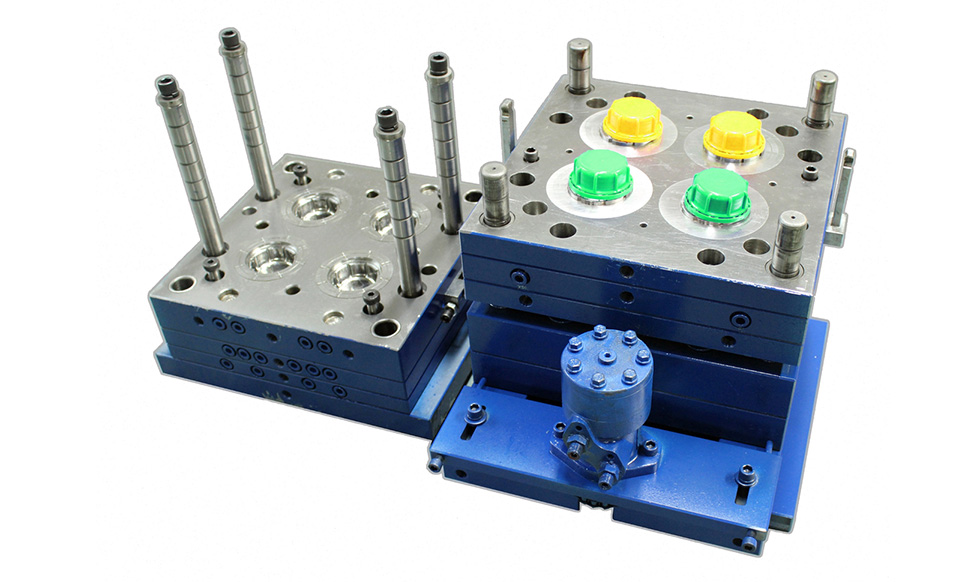

Multi Cavity Plastic Injection Bottle Cap Mold

Cap Mold Feature

1.Interchangeable insert is available for easy maintenance and long mould life.

2.Each cavity and core have independent cooling system, shortening production cycle time and getting high production efficiency.

3.Export standard mould; we are honest on steel material and mould components.

4.Testing mould and cap before shipping to your country, and we supply spare parts for you in one year if damage.

5.Tooling Machine is from Japan, which is good at precision machining to ensure low eccentricity.

English

English España

España