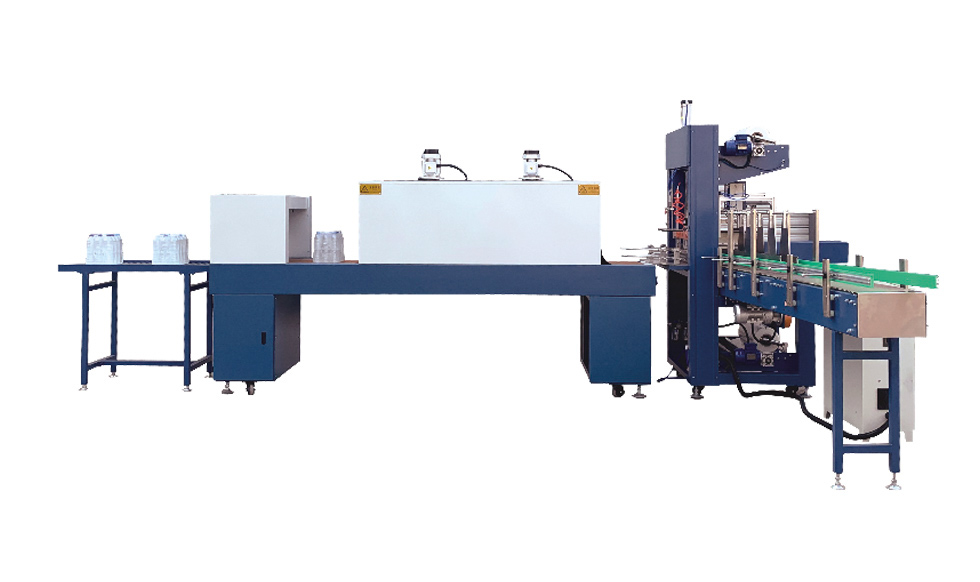

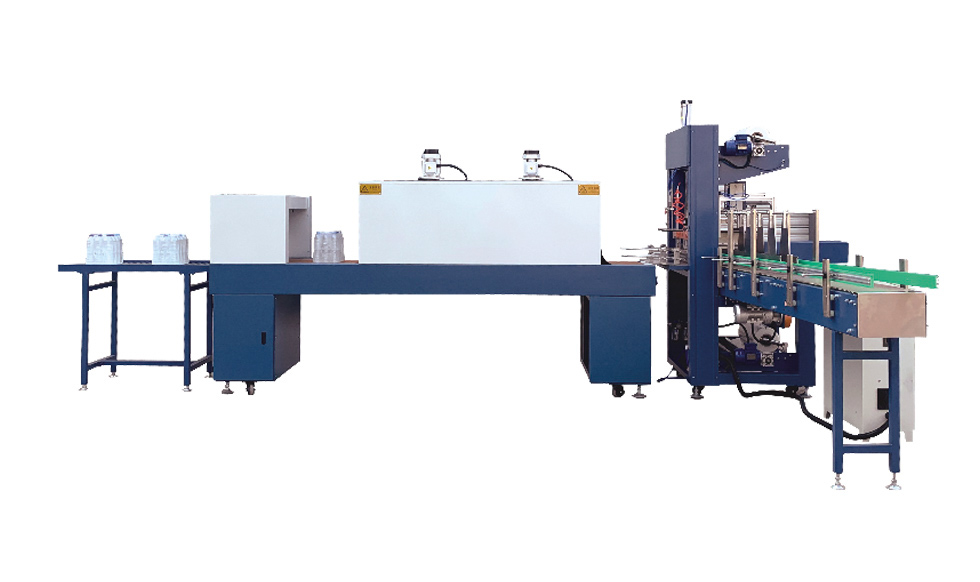

Process flow of heat shrink packaging machine

1. First set the heating time for the machine

2. After pressing the manual or automatic button, the solenoid valve of the rack cylinder gets electricity to drive the gear, and the gear drives the chain. At this time, the proximity switch at the rear of the rack cylinder is disconnected. When the rack cylinder runs to the top dead center, the front proximity switch of the rack cylinder is turned on, and the solenoid valve of the drying oven cylinder is energized and output.

3. When the oven cylinder runs to the top dead center, the timer starts and starts to delay, and the solenoid valve of the rack cylinder is powered off.

4. When the timing is over, the solenoid valve of the oven cylinder is powered off.

5. According to the work mode flag, decide whether to continue the next workflow.

1. Advanced Chinese touch screen control, easier operation;

2. Product packaging, printing the date at one time. Save time and save costs;

3. Optimized structural design, easier to disassemble and clean;

4. The temperature of horizontal and vertical sealing is independently controlled, which can better adapt to various packaging materials;

5. Intelligent design, no empty packaging when there is no blanking.

English

English España

España