Many factories now require low-pressure protection and debugging of injection molding machines. In fact, most technicians cannot adjust them quickly and well; just in the link of low-pressure adjustment, the adjustment time can be greatly saved, and the production performance can be improved. support. The following Liansheng injection molding machine will introduce the low-voltage protection and debugging methods of the injection molding machine, let us take a look.

1. Adjust the clamping pressure to the required pressure, which can be seen from the pressure gauge; for example, if we need a clamping pressure of 120KG, first straighten the crank and adjust the thickness of the injection molding machine mold until the clamping pressure on the pressure gauge is reached. Reach 120KG, then proceed to the next step.

2. The distance of the mold opening should not be too far. The principle is to take out the product without touching the product; note that when setting the mold opening buffer, the length of the buffer must be determined according to the mold opening speed. Far.

3. The first stage of slow mold opening is generally set according to the low-pressure starting position; note that if there is a heart pumping, ranking, etc., it is best to increase 5MM according to the mold closing position.

4. The fast clamping position is generally turned into a fast clamping action after the clamping section is started. The size of the fast tail position is determined according to the precision of the injection molding machine; the higher the precision, the smaller the position. Generally set at 20---40MM before the start of the low-pressure position.

5. First set the high-pressure pressurization speed of mold closing to 0, then manually close the mold, and set the number according to the position where the mold of the injection molding machine completely fits the front mold. For example, the matching position of the front and rear molds is 1.3MM, and the setting position is generally 1.4MM. When the set position is the same as the actual position, it is easy to falsely report, and if too much, the low-voltage protection will be lost.

6. Restore high pressure and high speed, return to normal, the entire low-pressure protection setting is completed, and test with white paper after completion; put the white paper on the mold of the injection molding machine, and after the mold is closed, slightly reduce the low-pressure position or reduce the speed and pressure. The entire debugging cycle does not exceed 5 minutes.

The above is the description of how to debug the low-pressure protection of large injection molding machines. Do you understand after reading it? I hope it is helpful to you.

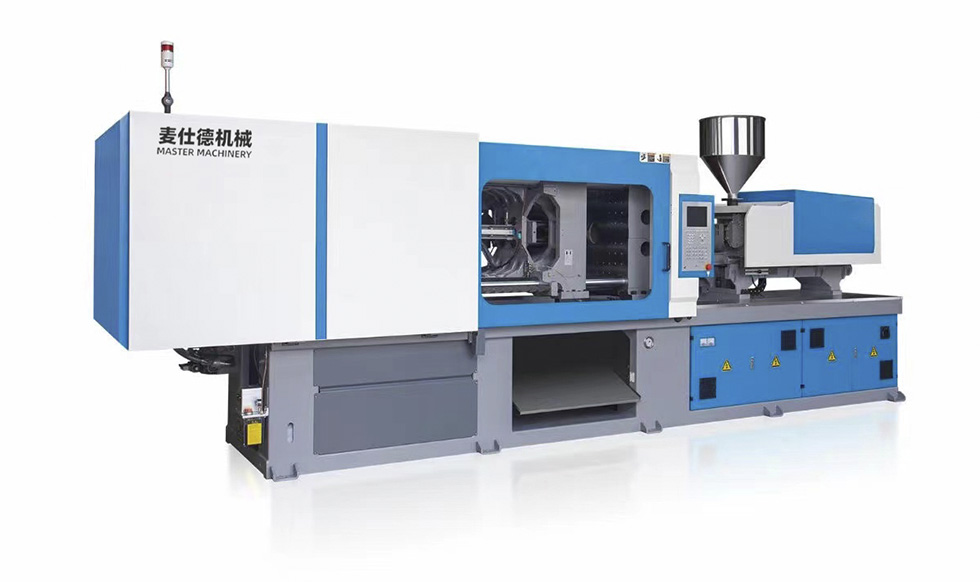

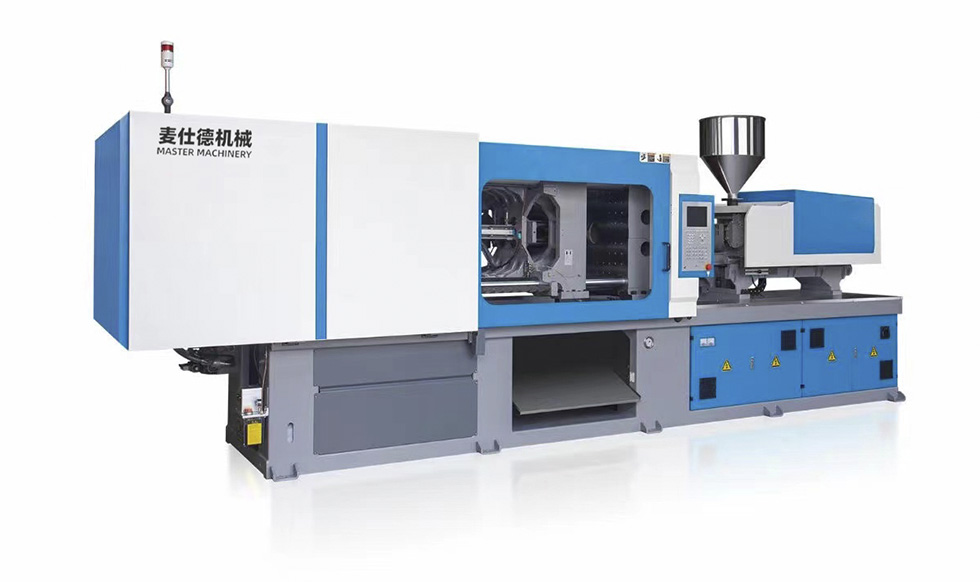

Horizontal Injection Molding Machine

Master Packing joint with Ningbo injection company to supply customers with 10T-4,000T, injection weight 45g---40,000g, more than 30 kinds of specification injection mold machine. Master injection machine has energy-saving, environment-friendly, low noise, high rigidity, excellent performance, fast response, and high efficiency. With advanced servo motor and famous brand parts, Master injection machine becomes many customers' optimal choice for Injection needs.

English

English España

España