What are the types of processing and molding of PET bottles?

Generally speaking, there are two types of molding methods for PET bottles, "direct blow molding" and "extension blow molding":

Direct blow molding method: This method is to first inject the molten preform on the same machine (usually called injection stretch blow molding machine: Injection Stretch Blow Molding), and then extend and blow molding in the hollow mold. Since the molding of the preform and the stretch blow molding are carried out in the same machine, it is called "One Step". Moreover, this method uses the heat retained by the preform to perform extended blowing when the preform has not yet cooled, so it is also called "hot preform method".

Stretch blow molding method: In this method, the preform is first shot out by an injection machine, and then the cooled preform is heated by a stretch blow molding machine, and is stretched and blown in a hollow mold. This method is called "two-stage molding method" because it undergoes secondary processing by injection machine and stretch blower. And this method is to heat and extend the air after the preform is cooled, so it is also called "cold preform method". The processing flow is as follows: dehumidifying and drying the PET raw material -> injecting the molten raw material into the mold with an injection machine -> cooling and forming the PET preform -> carrying out biaxial stretch blow molding with a stretch blow molding machine (Stretch Blow Molding). Note: The so-called "biaxial extension" means that the extension rod is used for longitudinal extension and the high-pressure air is used for transverse extension.

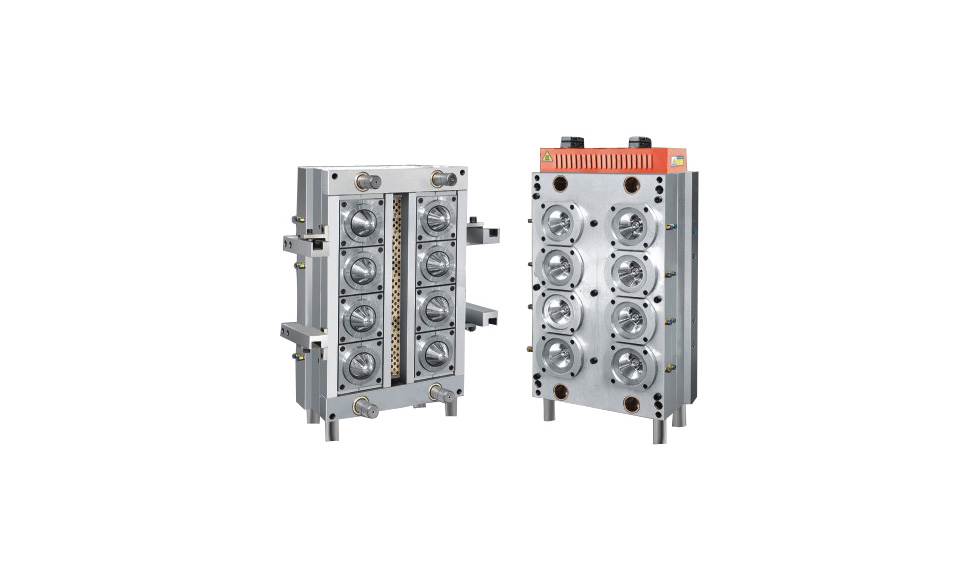

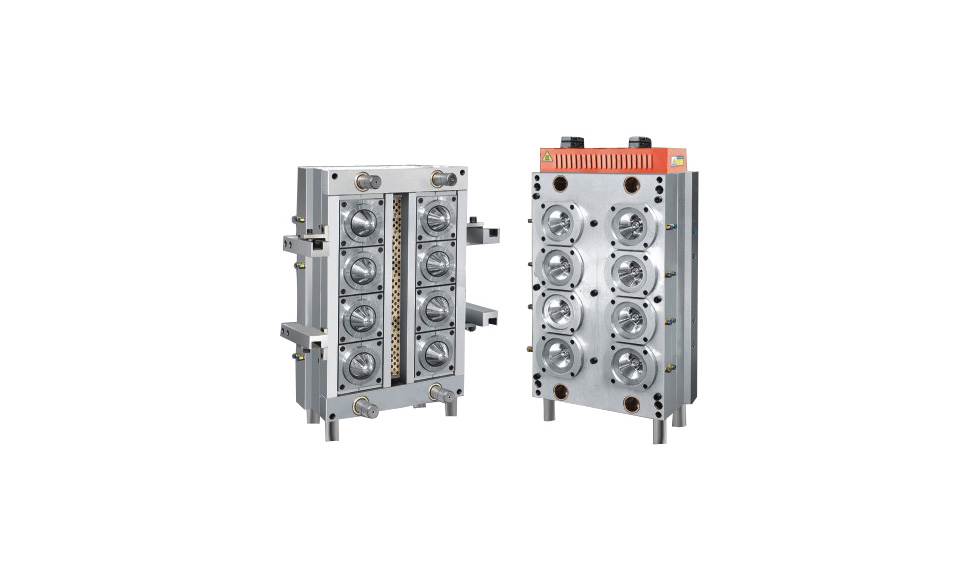

Applicability of the two: Generally speaking, the one-stage method is more suitable for the production of small quantities and many specifications, and the two-stage method is suitable for the production of large quantities and small specifications. The FT-P series provided by our company: special machine for PET bottle preform injection molding, which belongs to the two-stage molding method.

English

English España

España